Imagine this: You’re on the brink of launching your latest electronics project, maybe a new line of smart home devices or a cutting-edge piece of industrial tech. Everything is running smoothly—until you hit one last critical question: How do you keep it cool? You’ve got three options in front of you: AC fans, DC fans, or EC fans. But which one is right? What’s the difference? How do you decide without risking your project’s performance or efficiency? It’s not just about picking a fan—it’s about making sure your entire system works seamlessly. So, where do you start?

Here’s the short answer: AC, DC, and EC fans differ mainly in how they’re powered and how efficiently they run. AC fans use alternating current, which works well for bigger industrial settings but isn’t the best for energy savings. DC fans run on direct current, making them quieter and easier to control, which is great for more delicate electronics. EC fans combine both AC and DC advantages, offering good control and energy savings.

Now that you have the basics, let’s dig deeper to figure out which fan is truly the best fit for your specific cooling requirements.

What are AC Fan, DC Fan And EC Fan?

What is AC fan and its applications?

AC fans operate using alternating current (AC), such as 100V, 110V, 120V, 220V, 230V, 240V, 115V, 230V, 380V, the type of electrical power that’s typically supplied in homes and industrial settings.

Working Principle of AC Fan: The power voltage connected to an AC fan alternates between positive and negative, and it relies on circuit control to make two sets of coils work alternately, creating different magnetic fields.

Since the power frequency for an AC cooling fan is fixed, the speed at which the magnetic poles in the silicon steel sheets change is determined by this frequency. The higher the frequency, the faster the magnetic field switches, which theoretically increases the fan’s speed, similar to how a DC fan rotates faster with more poles. However, if the frequency is too high, it can make it difficult for the fan to start.

AC fans are used in various fields such as industrial ventilation, cooling, HVAC (heating, ventilation, and air conditioning), agriculture, and transportation.

What is DC fan and its applications?

DC fans, or direct current fans, operate using direct current (DC), such as 3V, 5V, 9V, 12V, 24V, 48V, ect., which means they require a stable and constant voltage source by a battery or a DC power supply.

Working Principle of DC Fan: According to Ampere’s right-hand rule, when current flows through a conductor, a magnetic field is generated around it. If this conductor is placed within another fixed magnetic field, it will experience either an attractive or repulsive force, causing the object to move.

Inside the blades of a DC cooling fan, a piece of pre-magnetized rubber magnet is attached. Surrounding the silicon steel sheets, two sets of coils are wound around the impeller shaft, and a Hall sensor is used as a synchronous detection device to control the circuit. This circuit alternates the operation of the two sets of coils wound around the shaft.

The silicon steel sheets generate different magnetic poles, which interact with the rubber magnet, creating an attractive or repulsive force. When this force exceeds the fan’s static friction, the blades start to rotate naturally. Since the Hall sensor provides synchronous signals, the blades can continue to operate. The direction of rotation is determined by Fleming’s right-hand rule.

DC fans are commonly used in fields such as computers, communication equipment, power supply, and small household appliances.

What is EC fan and its applications?

EC fans, or electronically commutated fans, combine the best features of both AC and DC fans by using a direct current (12V, 24V, 48V) motor but powered by an alternating current (110V~260V) supply. The key to their efficiency lies in their integrated electronics, which convert AC power to DC within the fan, allowing the motor to run on DC power while still being compatible with an AC power source.

Working Principle of EC Fan: The rotor of an EC fan is equipped with a magnetic rubber magnet, while the IC on the circuit board detects the exact position of the rotor’s N/S poles through the Hall sensor, current waveform, or back electromotive force (EMF) comparison.

By controlling the MOS switch, an electromagnetic field is generated when power is applied, which interacts with the rotor’s magnetic field. The resulting attraction and repulsion forces drive the fan’s rotation. The commutation signal synchronizes with the rotating magnetic field of the rotor and switches the current direction, allowing the fan to continue running.

EC fans are often used in fields such as air handling, ventilation, refrigeration, cooling equipment, and fresh air systems.

Key Differences Between AC Fan, DC Fan And EC Fan

Fan Power Comsuption

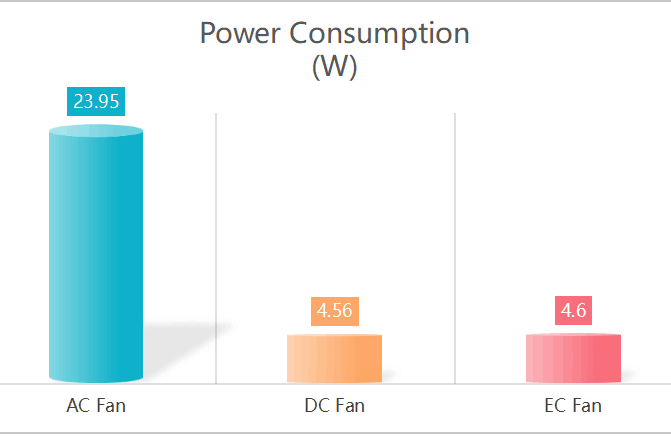

In order to provide you a clear piture how the differences go like on power comsuption between AC fan, DC fan and EC fan, we made samples and did some testings, all operating on 2600RPM and same fan size of 120x120x38mm.

| Fan Photos |  |  |   |

| Fan Types | 120x120x38mm AC Fan (220V, 50Hz) 2600RPM | 120x120x38mm 24VDC Series D 2600RPM | 120x120x38mm EC 220V Series D 2600RPM |

| Current | 0.109A | 0.19A | 0.052A |

| Power Consumption | 23.98W | 4.56W | 4.60W |

From the table you can see, AC fans get highest power consumption than DC and EC fans, saying nearly five times. In other words, DC and EC fans only account for 20% power comsuption comparing to AC fans on 2600RPM of 120x120x38mm size. This clearly shows that DC and EC fans are much more energy-efficient compared to AC fans.

It’s also worth noting that when EC and DC fans come from the same mold, the EC fan’s power consumption will be slightly higher than the DC fan’s. This is because the EC fan circuit is devided into two parts: the DC drive and the voltage step-down circuit from 220V to DC. This step-down process results in additional power loss, making the EC fan consume slightly more power than the DC fan, even at the same operating speed.

Fan Performance & Fan Noise

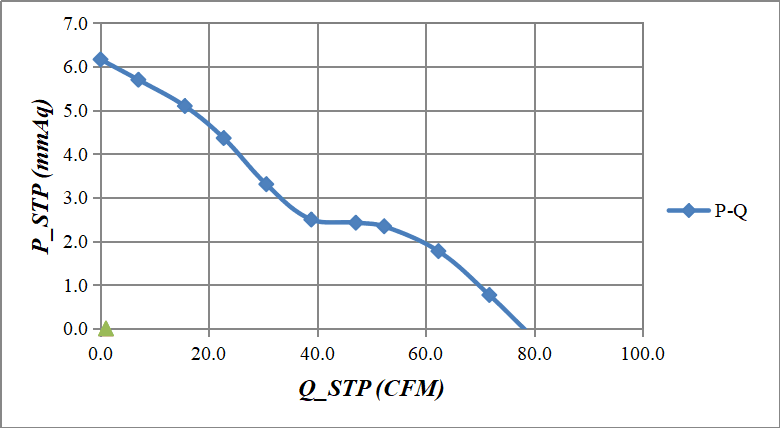

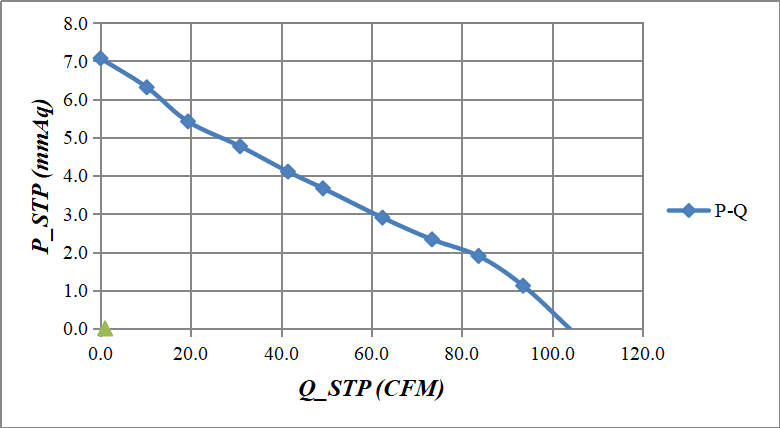

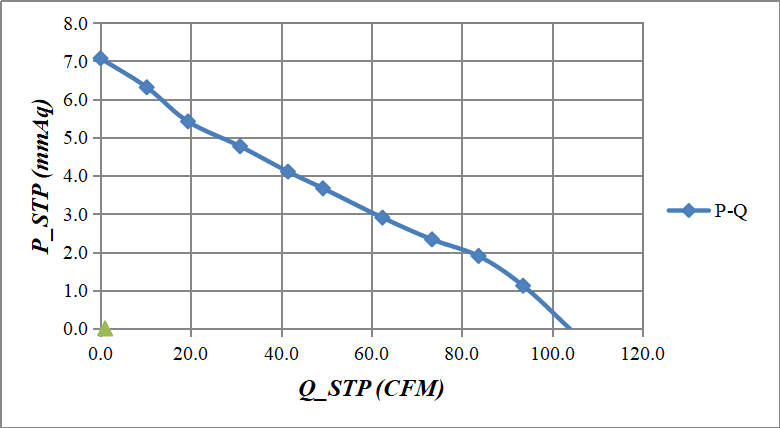

We also tested the fan airflow, air pressure and noise of AC fan, DC fan and EC fan, all operating on 2600RPM and same fan size of 120x120x38mm.

| Testing Pictures |  |  |  |

| Testing Pictures | 120x120x38mm AC Fan (220V, 50Hz) 2600RPM | 120x120x38mm 24VDC Series D 2600RPM | 120x120x38mm EC 24V Series D 2600RPM |

| Air Flow | 78.25cfm | 104.29cfm | 104.29cfm |

| Air Pressuure | 5.95mmAQ | 6.28mmAQ | 6.28mmAQ |

| Noise | 41.3dBA | 45.3dBA | 45.3dBA |

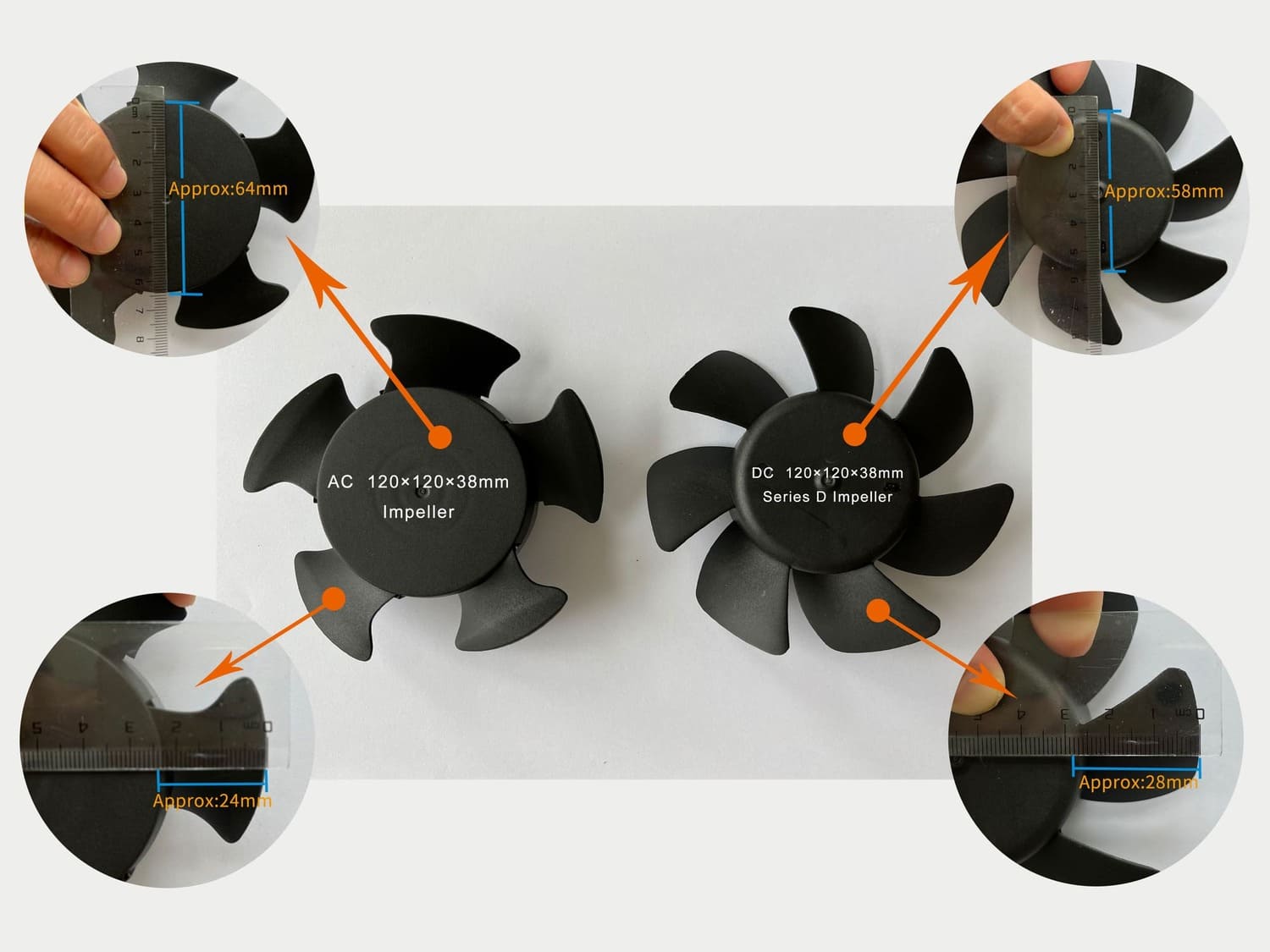

From the table you can see, AC fan gets less airflow than DC fan & EC fan, saying only 75%. The reason is that normally AC gets bigger motor size, but shorter impeller length comparing to DC & EC fans.

Are you curious to know why AC fan has to get bigger motor size? AC fans rely on the 50/60Hz frequency of mains electricity for commutation, which can easily lead to commutation issues, causing the rotor’s magnetic poles to tilt. The unbalanced magnetic field results in most of the power being lost as heat, leading to low efficiency. As a result, the motor needs to be large enough to generate sufficient driving force, which is why AC fan motors are typically larger.

Due to the lower air flow, AC fan gets lower noise. However, when AC fan gets same airflow same as DC and EC fans, its noise should be higher than DC and EC fans.

As a note, when DC and EC fans work on same mold design, their fan performance and noise will remain as the same. Usually, EC fans are improved on the basic of DC fan’s strcuture.

Fan Speed Control

AC fan cannot be speed controlled because its speed regulation typically depends on the frequency of the AC power, which is determined by the power grid and cannot be directly changed by the user. Additionally, the structure and working principle of AC fan limit their ability to adjust speed, meaning they can only operate at a fixed speed.

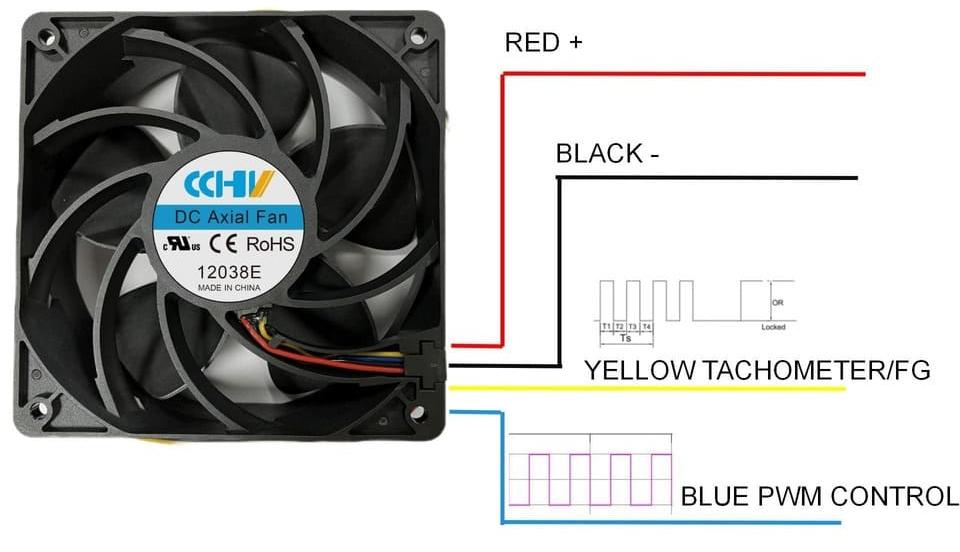

In contrast, DC fan and EC fan have speed control functions. DC fan adjusts speed normally by changing the voltage or by PWM duty cycle (click here for more information), while EC fans achieve precise speed control through an electronic controller. These fans are suitable for applications that require accurate airflow control, such as computer cooling and air conditioning systems.

Fan Size Limitations

One important aspect to consider when comparing AC, DC, and EC fans is the size limitation. AC fans in the market generally start at a minimum size of 80x80x25mm, while EC fans are available at a slightly smaller minimum size of 60x60x25mm. However, DC fans can be manufactured as small as 15x15x4mm, making them far more flexible in terms of size and design options.

AC Fan Size Limitation Analysis

From point 2 of fan performance and fan noise differences, we come to know that AC fans require larger motors to generate the necessary driving force. Consequently, it’s challenging to reduce the size of AC fans without sacrificing performance and efficiency.

This is because, when the motor is large, the design of smaller fan sizes results in shorter fan blades. Shorter blades are less capable of moving a significant volume of air, which means the airflow is not sufficient to meet cooling requirements. As a result, smaller AC fans often fail to deliver adequate cooling performance, limiting their use in applications that demand compact and efficient cooling solutions.

EC Fan Size Limitation Analysis

EC fans have a size limitation due to the integrated electronics that convert AC to DC within the fan.

The circuit design of an EC fan includes additional components, such as electrolytic capacitors, which are not found in a DC fan. As a result, the PCB of an EC fan requires more space compared to that of a DC fan. To accommodate the EC fan’s larger PCB within the existing mold of a DC fan, the number of silicon steel sheets is reduced to make room. However, with fewer silicon steel sheets, the fan’s speed must be decreased to keep the coil’s temperature rise within the controlled limits. If the speed were kept high, the coil’s temperature would exceed the standard control threshold. This explains why EC fans tend to be larger in size than DC fans.

.jpg)

Why DC Fans Are More Flexible in Size

On the other hand, DC fans can be manufactured in much smaller sizes, such as 15x15x4mm, because they don’t need large windings or built-in electronics to convert current. Direct current allows for more compact and efficient designs, making DC fans ideal for small electronics like small home appliances, laptops, and other devices that require precision cooling in a limited space. The flexibility in sizing gives DC fans a clear advantage in applications where space is tight and a compact cooling solution is needed.

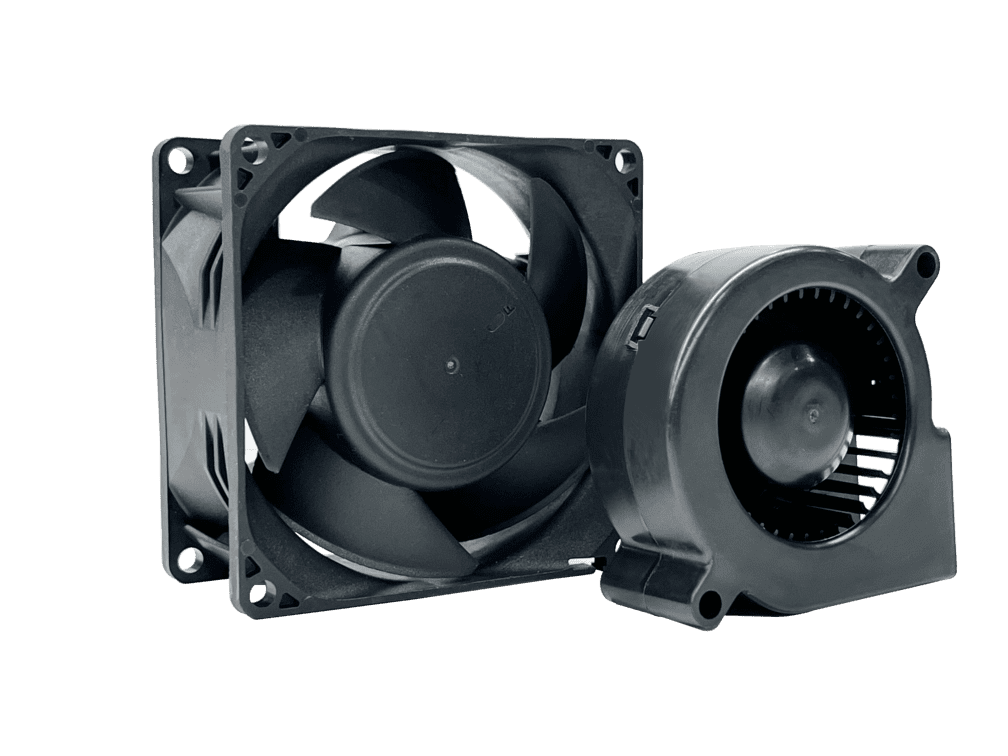

Founded in 2006, CCHV is China top DC/EC axial fans and DC Blowers manufacturer. Led by experienced engineers from Taiwan fan companies, we have developed a full range of high performance DC fans from 15mm to 220mm with different IP ratings which should perfectly meet different requirements for different industries.

Here you can see some of our popular small DC axial fan models. If any interest, please don’t hesitate to contact us!

Cost

AC fans have relatively low costs due to their mature technology, simple structure and easy production.

DC fans usually come with a moderate cost. They are more expensive than AC fans exspecially when the additional functions required for controlling speed.

EC fans have the highest cost among the three types. This is due to the advanced electronics and technology required to convert AC power to DC and offer precise control over the fan’s operation.

Conclusions

When choosing between AC, DC, and EC fans for your cooling needs, it’s crucial to consider your specific project requirements, including power consumption, fan size, noise levels, and control options.

- AC fans are best suited for industrial settings where initial cost and simplicity are important, but they fall short in terms of energy efficiency, control, and noise reduction.

- DC fans offer significant advantages for smaller electronic applications due to their energy efficiency, size flexibility, and low noise, making them ideal for devices requiring precise cooling and space-saving designs.

- EC fans combine the benefits of both AC and DC fans, providing energy efficiency, precise control, and high performance. Although they come with a higher upfront cost, their long-term benefits in energy savings and flexibility make them a worthy investment for more advanced systems.

FAQ

Q1:What is the difference between an AC and DC fan?

A1: The key difference between AC and DC fans is their power source and efficiency. AC fans use alternating current and are ideal for larger, industrial applications but consume more energy. DC fans use direct current, offering greater energy efficiency, quieter operation, and speed control, making them better suited for smaller electronics.

Q2: Is an EC fan better than a DC fan?

A2: EC fans combine the best features of both AC and DC fans, offering energy efficiency like DC fans while running on an AC power source. However, EC fans are typically more expensive due to advanced electronics. If cost is a priority, DC fans may be more suitable for smaller applications.

Q3: Can AC fans be used for electronics cooling?

A3: AC fans are generally not ideal for electronics cooling due to their larger size, higher power consumption, and lack of speed control. They are better suited for industrial applications. For electronics, DC fans or EC fans are preferred as they offer better energy efficiency, compact size, and precise airflow control.

Q4: Which fan type is the most energy-efficient?

A2: The most energy-efficient fan type is the DC fan, consuming significantly less power than AC fans—around 20% at similar operating speeds. EC fans are also highly efficient, combining DC performance with AC compatibility, though they consume slightly more power than DC fans due to their internal AC-to-DC conversion.

Q5: What are the size limitations of AC, DC, and EC fans?

A5: AC fans typically start at a minimum size of 80x80x25mm due to their larger motor requirements. EC fans are slightly smaller, beginning at 60x60x25mm. In contrast, DC fans offer greater flexibility, with sizes starting as small as 15x15x4mm, making them ideal for compact applications.

Q6: What is the lifespan of AC, EC fans and DC fans?

A6: Since EC fan is upgraded based on DC fan mold, therefore, lifespan of DC fan & EC fans keep at the same, saying 50000-70000 hours at 40℃. And Lifetime of AC fan is 30000-50000 hours at 40℃.