- China Top DC Fans & Blowers Manufacturer

- anniech(at)dcfanmfg.com

- +86-13538992575

CCHV designs and manufactures a wide range of DC fans and blowers, offering sizes from 15mm to 225mm and voltages of 3V, 5V, 9V, 12V, 24V, 48V and other custom voltages. Our DC fans and blowers, featuring hydraulic & ball bearings and IP55 to IP68 ratings, are customizable for various industrial needs, backed by a in-house and experienced R&D team. From this page, you can get our fan datasheets and basic fan knowledges, which helps you understand what behind the fan you are getting.

Bugün bize yazın! Deneyimli mühendislerimiz sizinle iletişime geçecek within 12 hours.

Normally, most of the users select DC fans by referring to its maximum air flow and air pressure, which is not the comprehensive thinking since maximum air flow and air pressure are tested under ideal conditions, which doesn’t exist in real applications since there is always impedance in your system. There are 5 steps to guide you how to get the right fan with right air flow to optimize your system cooling.

After deciding the fan size, air flow and noise to match your system, the following basic knowledge can help to understand which type of the fan you have to consider for optimzing your budget with expecting fan lifetime.

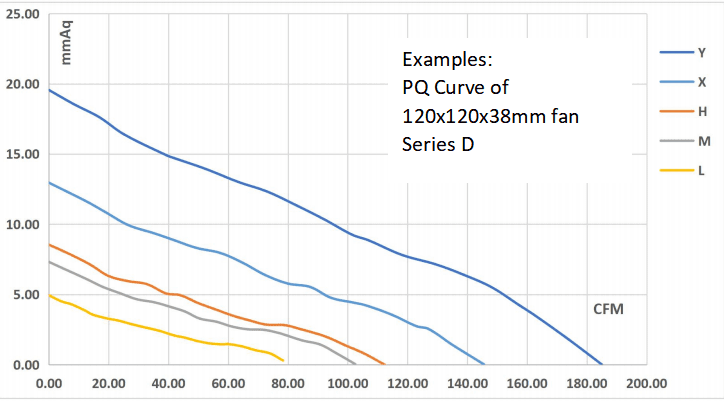

Fan air flow & air pressure and noise are two key indicators to present each fan performance. Normally, the higher for air flow and air pressure, the higher of the fan noise. Excellent engineers can make optimal design with higher air flow but keeping on same noise and even lower. At CCHV, you can enjoy our optimal design to customize your needs.

Fan performance is presented by PQ curve, which fully demonstrates its performance under various impedances.

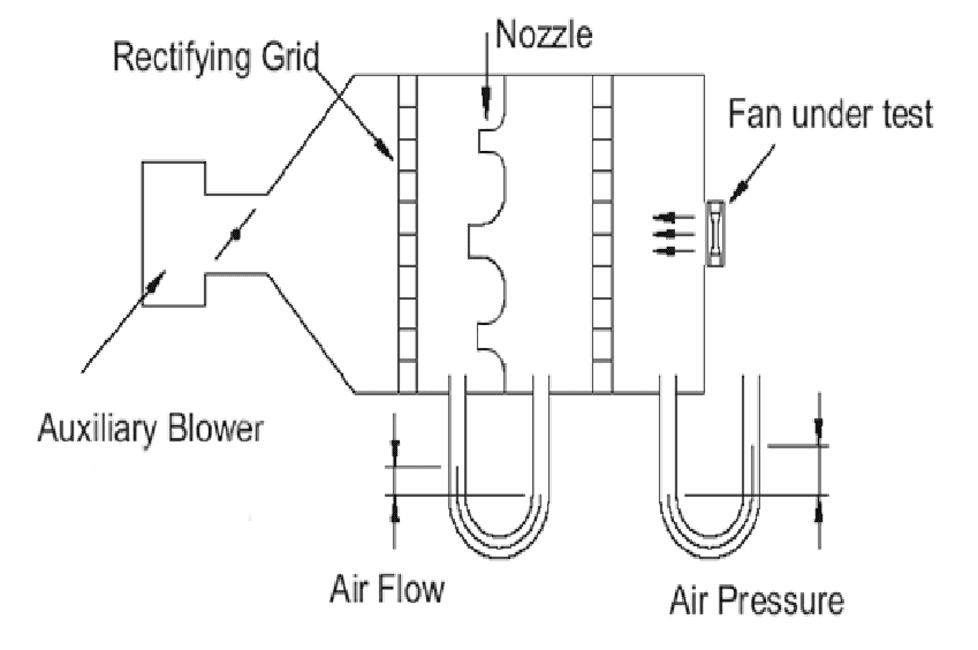

PQ curve is measured by wind tunnel. The maximum air flow and air pressure are measured values under ideal conditions. Max. air flow means there is no pressure difference between the air inlet and air outlet. Max. air pressure means the difference between inside and outside of wind tunnel till the air flow is zero when the fan blows the air into the air tunnel. The relationship between them is the air flow decreases with the increase of the air pressure.

By adjusting the Nozzle and the Auxiliary Blower, to control the air volume, record the corresponding difference values between Air Flow and Air Pressure, then finally draw the pressure-flow diagram, saying PQ curve diagram.

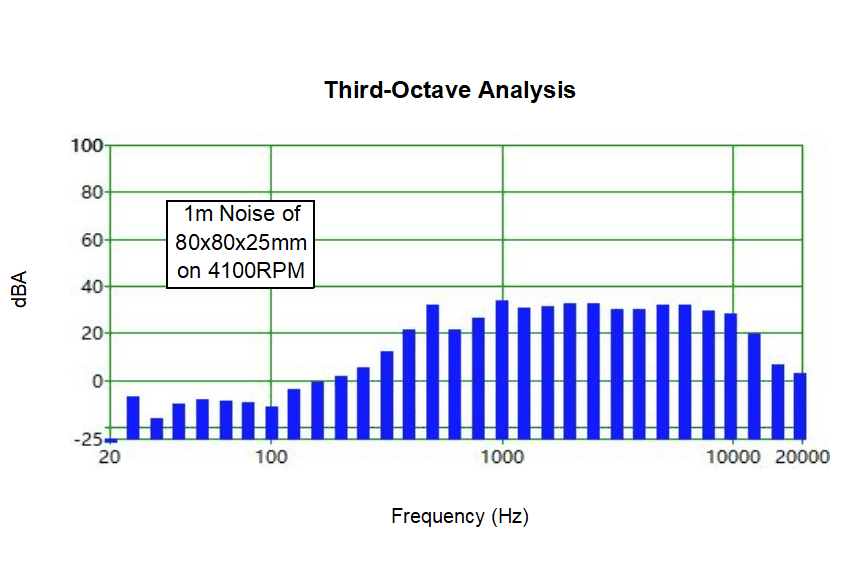

When the fan is working, it makes noise. The fan noise is divided into flow noise, motor/electronics noise. The flowing air interferes with each other, frictions with surrounding objects and the separation effect of the impellers on the airflow etc., will all generate noise. The higher of the fan speed, the more of turbulance and the greater of fan noise. The motor/electronics noise normally apprears at the low speed, which is sensitive on consumer electronics products.

Fan acoustic measurements must be carried out in a specialized semi-anechoic chamber whose roof and walls are covered with sound-absorbing materials.

CCHV gets own acoustic chamber, whose background noise is as low as 9dBA with compliance to international standard. Normally, the fan noise is measured one meter from fan inlet at rated voltage.

Bearing system is the “heart” of DC fans, which, to a large extent, determines the fan lifespan. There are mainly two types of bearings popular in the market. The following descriptions and comparisons can help you to get your right bearing system for your applications.

Hidrolik/tüfek yatağı, yağlamak için döngüsel oluklar alarak, yaygın kovan yatağını geliştirmiş bir yataktır ve çözmek için kullanılır Sızıntı sorunu. Hidrolik ve kovan yatakları, metalurji yoluyla bakır ve demir tozundan yapılmış sinterlenmiş gövdelerdir.

Ball bearing is a kind of rolling bearing, the spherical alloy steel ball installed in the middle of the inner ring and the outer ring, in a rolling way to reduce the friction in the process of power transmission and improve the efficiency of mechanical power transmission.

Hangi rulman türünün sizin için en uygun olduğuna karar verdikten sonra, burada fan performansını en üst düzeye çıkarmak için fan yapısının tasarımı hakkında ek bilgiler bulabilirsiniz.

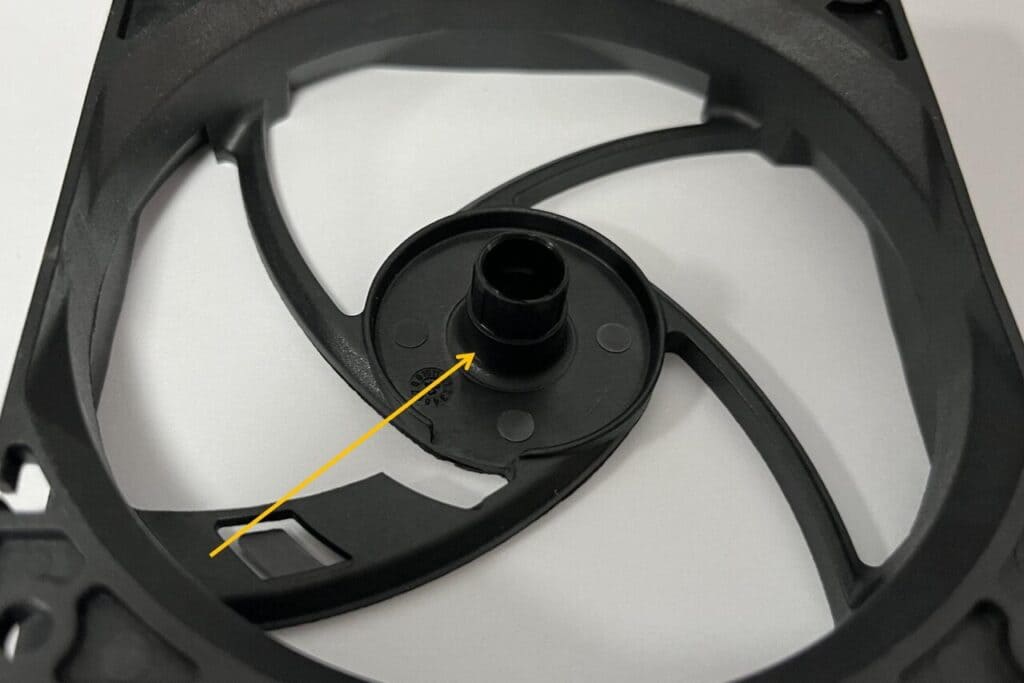

Şaft tabanının ve çerçeve orta tüpünün normal tipi, aşağıdaki resimlerde gösterildiği gibi plastikten yapılmıştır ve fan, normal sıcaklıkta düşük hızda çalışırken hidrolik rulman ile kullanılır.

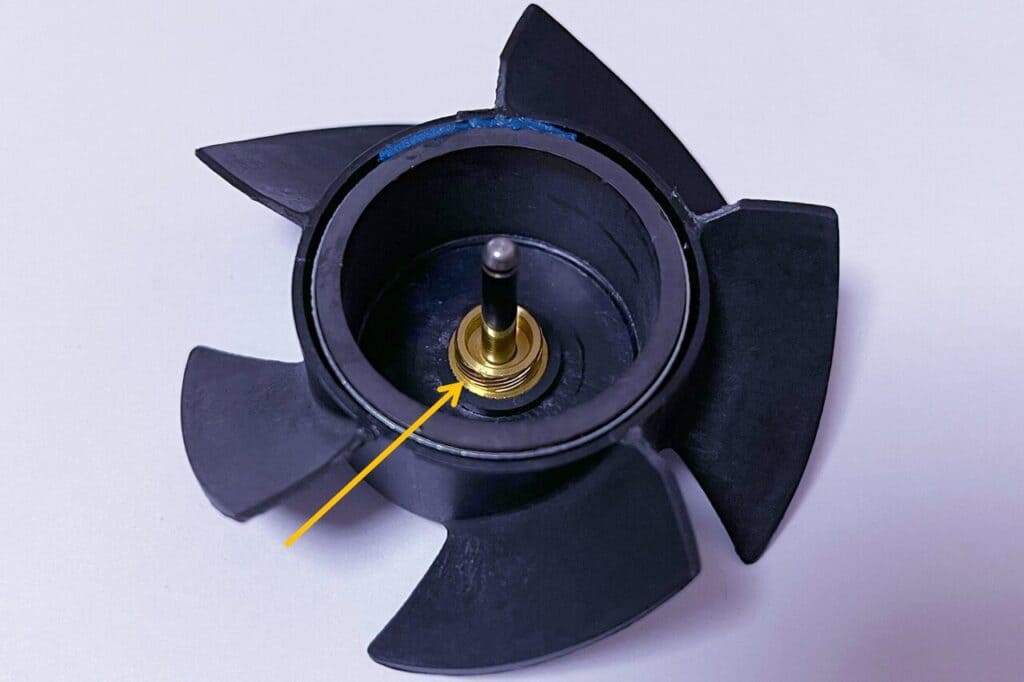

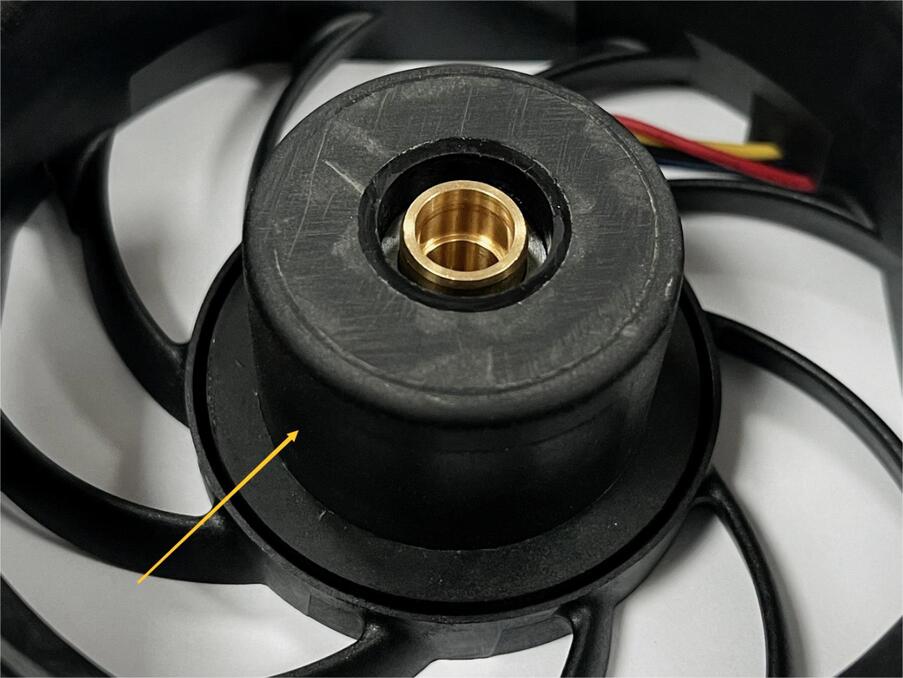

High reliable type of shaft base and frame middle tube are made of pure copper as the following picture. Copper base and copper tube gets more accurate and better cooling effect when operating at the high speed, which are normally used with dual ball bearing.

Different IC functions can help you to know how the fan works under what status. PWM function can improve the fan energy effeciency by speed control. Here you can find out the waveforms of different IC functions.

RD signal is used to detect whether the fan is running or not. When the fan is normally running, the output level is low, whereas, high output level means the fan is stopped.

FG Signal, as known as Tacho Signal, is to provide a square wave signal from the fan, and the signal frequency represents the speed of the fan, which means FG conveys speed info in the form of square waves and normally it works with PWM.

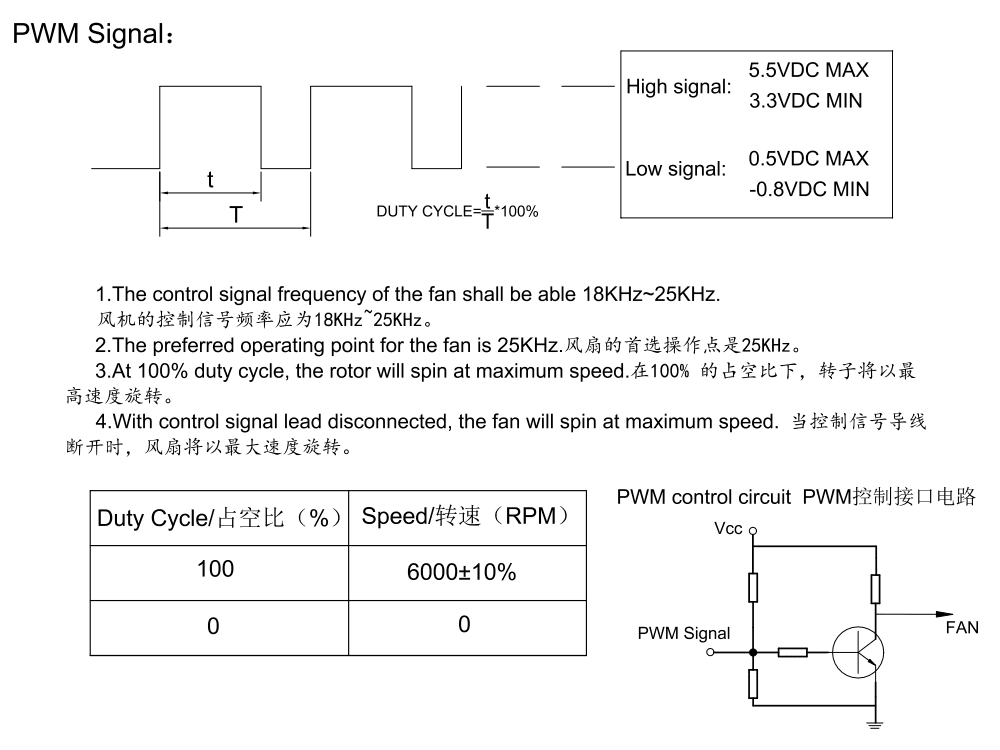

The fan speed can be controlled by Pulse Width Modulation. PWM periodically outputs the voltage at a certain time, which is called the duty cycle, usually expressed as a percentage.

To make fan easily connecting with your control board, EagleCooleer offers various connector solutions. Here are only some popular types. Contact us for your suitable model No..

Some parts of DC fans are used for outdoor, facing challenges against harsh enviroment, like dusty, high temperature, high humidity, corrosive, ect.. We understand the importance of environmental protection and offer different IP levels tailored to your unique needs.

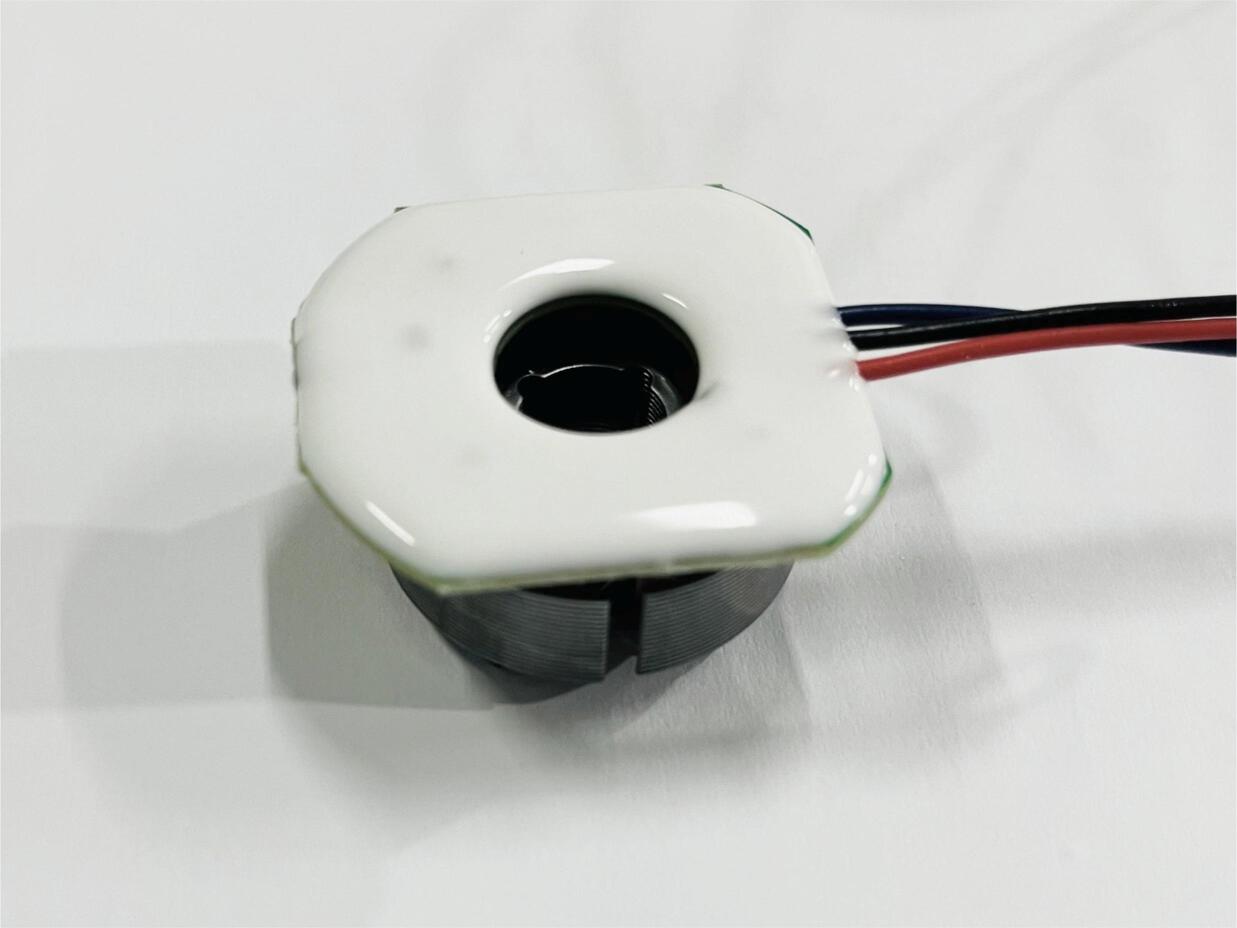

(By PCB Gluing)

(By Whole PCB Potting)

(By Whole Stator Coating)

Get more information how we number our fan models.

CH

CCHV

(a)

Electrictal Character:

A: Standard 2PIN

T: Frequency generation

or more

60

Fan Dimentions:

15mmx15mm

17mmx17mm

20mmx20mm

30mmx30mm

35mmx35mm

40mmx40mm

45mmx45mm

50mmx50mm

60mmx60mm

70mmx70mm

80mmx80mm

92mmx92mm

100mmx100mm

120mmx120mm

140mmx140mm

12

Voltage:

05: 5V

09: 9V

12: 12V

24: 24V

48: 48V

(b)

Bearing Type:

S: Sleeve Bearing

R: Rifle/Hydraulic Bearing

B: Dual Ball Bearing

L

Speed:

L: Low Speed

M: Middle Speed

H: High Speed

X: Higher Speed

Y: Very High Speed

U: Pretty High Speed

V: Super High Speed

P: Exemtely High Speed

–

(c)

Wire Functions:

A/Leave Blank: no function, only positive and negative wires

R: FG/RD & Lock Protection & Automatic Restart

S: Temperature Control & Lock Protection & Automatic Restart

W: PWM & Lock Protection & Automatic Restart

25

Frame Height:

1: 1mm

3: 3mm

4: 4mm

7: 7mm

10: 10mm

15: 15mm

20: 20mm

25: 25mm

32: 32mm

38: 38mm

51: 51mm

b

Mold Series

Following our blogs, you can stay informed about DC fan technology, industry updates, practical tips, and our latest designs to elevate your system. Let us empower your businesses with the DC fan knowledge needed to stay ahead in the competitive market. Together, let’s create a brighter future!

Should you have any questions or requirements about DC fans, especially the high performance DC fans, please feel free to contact us for further communication.

WhatsApp us

Contact us now if you need help to get the right fan for your cooling solutions. We’ll in touch with you within 6 hours.