After spending countless hours diving into blogs and watching videos on the seemingly simple question, “Is a 3D Printer Fan Essential?”, I’ve emerged with a clearer perspective that I’m eager to share with you.

So, to answer our burning question: it’s not a simple yes or no. The fan’s importance varies depending on what types of plastics and how you’re printing. Join me as we delve deeper, sifting through the noise to unveil the genuine role of the cooling fan in our 3D printing adventures.

Common 3D Printing Plastics Materials

Firstly, let’s dive in by offering some invaluable insights into the world of 3D printing materials. In the ever-evolving market of 3D printing, plastic materials reign supreme. They take up the lion’s share of the market and are generally categorized into two primary types: thermoplastics and photopolymers. So, what’s the breakdown? Well, in 2022, thermoplastics carved out 59% of the plastic material landscape in 3D printing, with photopolymers trailing at 41%.

Ever heard of photopolymers? These fascinating materials undergo a transformation when they come into contact with light. Imagine you’re a superhero, and light is your power source. Photopolymers are kind of like that. They change their state when zapped with light radiation. It’s cutting-edge technology like this that separates 3D printing from traditional manufacturing methods.

And what about thermoplastics? Names like PLA, ABS, PA/Nylon, TPU, and PETG are often front and center. The rising popularity of 3D printing has sparked a surge in demand for ABS and PLA materials. Globally, PLA stands as the most favored plastic filament in 3D printing. For a deeper dive into the characteristics, printing conditions, applications, and whether or not a cooling fan is essential for common 3D thermoplastics, check out the table below.

| PLA | ABS | TPU | PETG | PA/Nylon | |

| Strength | High | High | Medium | High | High |

| Toughness | Low | Medium | Pretty High | Medium | Medium |

| Durability | Medium | High | Pretty High | High | High |

| Glass Transition Temperature | 60ºC – 65ºC | 105°C | -50℃ – 0℃ | 85°C – 90°C | 50℃ – 80℃ |

| Printing Temperature | 190°C – 220°C | 220°C – 250°C | 225°C – 245°C | 230°C – 250°C | 220°C – 270°C |

| Heated Bed Temperature | 45°C – 60°C or Unnecessary | 95°C – 110°C Recommended | 45°C – 60°C or Unnecessary | 75°C – 90°C Necessary | 70°C – 90°C Necessary |

| Platform Adhesive Surface | Masking Paper, Glue stick, Glass Plate, PEI | Kapon Tape, ABS Paste | PEI, Masking Paper | Masking Paper, Glue stick | PEI, Glue Stick |

| Shrinkage/Warping | Low | High | Low | Pretty Low | Pretty High, Higher than ABS |

| Aplicações | Suitable for printing common objects including: models, low-wear toys, proofing parts and containers. It can be widely used in large surface models and practical products, such as furniture accessories, decoration, outdoor decoration and other fields. | Often used in the production of household and consumer products, including Legos and bicycle helmets. | Main applications: automotive parts, machinery (industrial parts), all kinds of gears, shock-proof parts, covers, connectors, rubber plugs, printing rollers, etc. Footwear: women’s shoes heels, ski boots, safety boots, high-grade soles, pipes, hoses, etc. | A wider range of applications, including functional prototypes, end products, brackets, parts, household gadgets and robotic parts. | Suitable for parts used in harsh environments, such as gears, engine mounts, pipe connectors or high-speed airflow tubes. |

| Others | Cooling Fan Necessary | Enclosure recommended; Thermostat recommended; 10%-30% cooling fan speed after first several layers printing; | Cooling Fan Necessary | Cooling Fan Necessary | Enclosure recommended; Thermostat recommended; Metal repair compound may be required. |

Does PLA printing need cooling fan? Definately, yes!

First things first, let’s talk about the ‘glass transition temperature’ as you see from above sheet, a term that might sound a bit technical but is essentially the sweet spot where the PLA transitions from a hard, glassy state to a soft, moldable one. But why is this important, you ask? Well, this magic happens typically between 60°C to 65°C, setting the stage for the perfect 3D printing environment.

Now, onto the deposition temperature, which is the heat level where the PLA is initially laid down, ranging between a hot 190°C to 220°C. Notice the difference here? Yes, there is a significant gap between this and the glass transition temperature, creating a window of opportunity for the cooling fans to step in and work their magic, ensuring a swift and controlled transition from molten to solid state, helping the PLA maintain its desired shape.

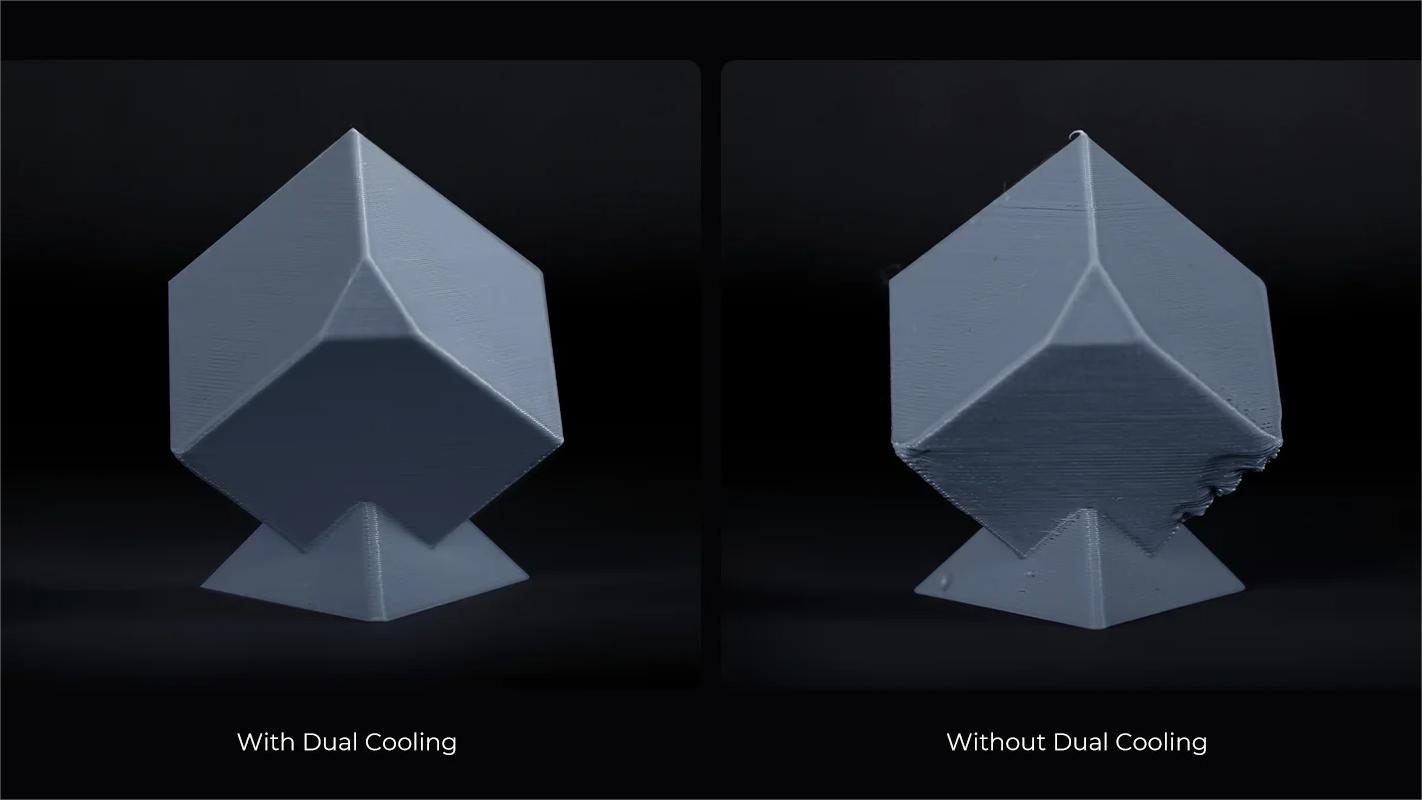

Ever wondered why your prints come out less than perfect?

It could very well be due to the underutilization of cooling fans. These guardians of the 3D printing process assist in rapidly cooling the PLA from its molten state back to solid, enhancing the structural integrity and the aesthetics of your prints. It’s like having a personal assistant that ensures everything retains its ideal form!

It’s not just about having a cooling fan, but setting it at the optimal speed is the real game-changer. Did you know that during 3D printing with PLA, cranking up the cooling fan speed to a full 100% can be the golden ticket to achieving those pristine prints? Yes, it’s that simple yet transformative adjustment that can elevate your 3D printing game to new heights.

Here, you can go through the hot video why needs cooling fan with PLA printing.

Does ABS printing need cooling fan? Recommended!

Many blogs and videos suggest that using a cooling fan isn’t necessary when printing with ABS since ABS has a higher glass transition temperature—around 105°C—compared to PLA, making it more resistant to quick changes in temperature. Conventional wisdom suggests that rapidly cooling ABS might lead to brittleness, causing issues like cracking or layer separation during the printing process. Another challenge is the tendency for ABS to warp, which can be exacerbated if a cooling fan is used.

However, this isn’t always true. It’s crucial to note that most ABS printing is carried out in a closed environment or enclosure. Since ABS printing requires a heated bed and operates at high temperatures—ranging from 220°C to 250°C—the ambient temperature of the enclosure can become quite hot. In this context, the cooling fan is pulling in warm air and blowing out warm air, not causing rapid cooling. Consequently, the fan doesn’t exacerbate issues like layer separation or warping but helps in maintaining a stable internal environment. This perspective is often overlooked but is vital for anyone planning to 3D print with ABS.

In addtion, not all ABS materials are created equal. Variations in ABS formulations from different manufacturers can add complexity to the 3D printing process. So, if you find that you’re not getting the perfect print with one brand of ABS while keeping the cooling fan off, it might be worth switching things up a bit. Consider turning on the cooling fan, perhas at a lower speed, as a new test with a different brand of ABS. It could very well solve the problems you’re facing and lead to a more successful printing experience.

If you opt to use a cooling fan while 3D printing with ABS, it’s important to ensure that the fan speed isn’t set too high. A general recommendation is to keep the fan speed between 10%-30%. In situations where the enclosure’s internal temperature is particularly high, a faster fan speed within this range may be beneficial.

However, it’s essential to remember that the cooling fan should be turned off for the initial layers of the print. This helps in laying down a stable foundation for the object you’re printing, reducing the risk of warping or other print deformities. This nuanced approach helps you get the most out of your ABS printing experience, considering both material-specific and environmental factors.

Using an enclosure during ABS printing

In the above content, we mentioned that in the majority of cases, ABS printing needs to be conducted inside an enclosure. Now, let’s explore the reasons for this together. Firstly, ABS is prone to shrinkage, making it vulnerable to temperature fluctuations and airflow during the printing process. An enclosure can help maintain a consistent internal environment, reducing the likelihood of disruptions caused by external conditions. A sealed box with a temperature control system can go a long way in ensuring that your ABS print turns out as intended.

Another vital consideration is the strong fumes that ABS printing emits. Long-term exposure to these fumes can be detrimental to your health. As such, it’s imperative to have proper air circulation or air filtration in place. Installing an air filtration system or making provisions to vent the fumes outside can protect you from the potentially harmful effects of ABS printing.

Summary

In this article, we’ve delved deep into the intricacies of 3D printing, particularly focusing on ABS materials. We’ve dispelled some common myths surrounding the use of cooling fans during ABS printing. Most notably, we emphasized that ABS printing often requires an enclosure to maintain a consistent internal temperature, which can actually make cooling fans useful. Varying characteristics among ABS materials from different manufacturers also mean that a cooling fan can sometimes be your ticket to a perfect print. However, we recommend keeping the fan speed to a modest 10%-30% to avoid rapid cooling and warping. Our aim has been to provide you with a comprehensive guide, addressing all the potential questions you may have about the role of cooling fans in ABS 3D printing.

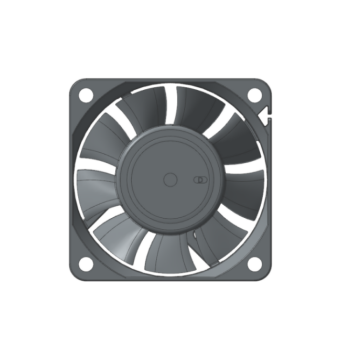

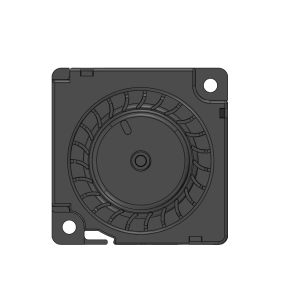

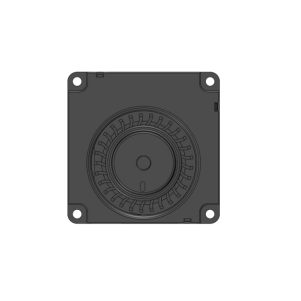

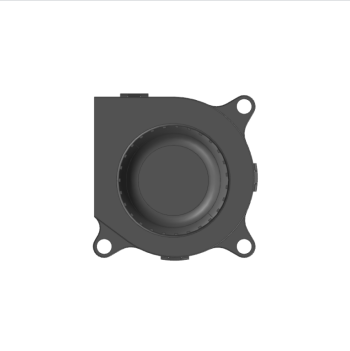

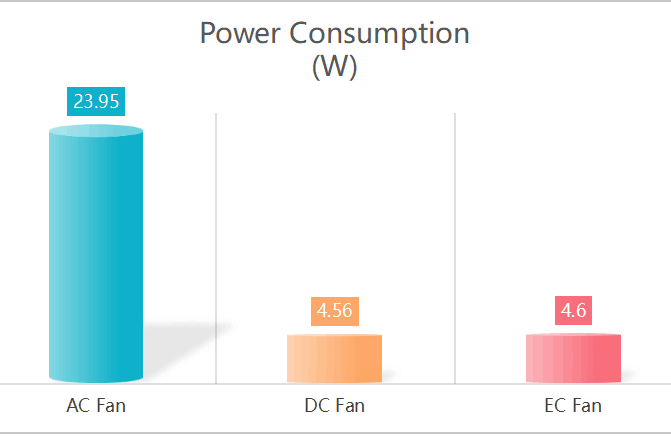

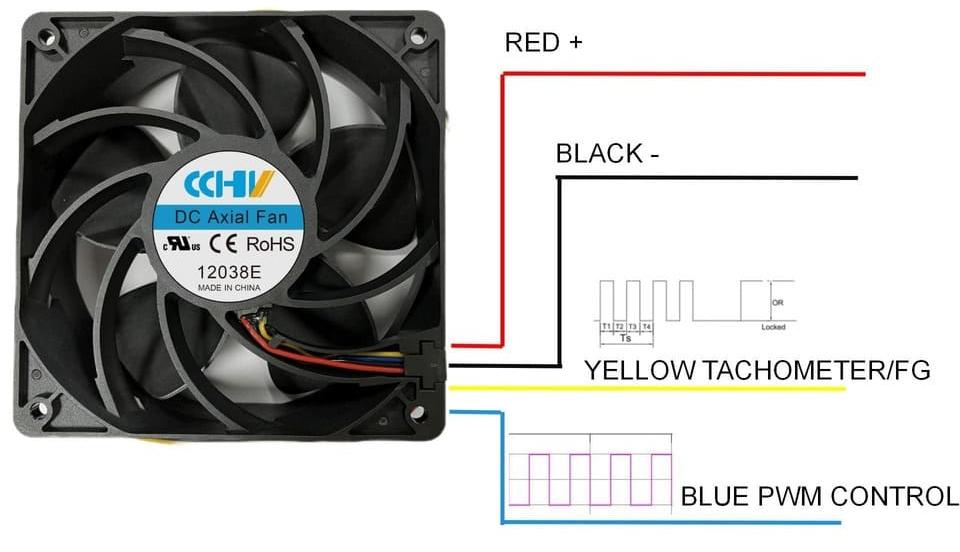

3D printer fans require high air flow and wide range of voltage. CCHV is leading DC fans manufacturer for 3D printer in China and have cooperated with Creality (China top 3D printer Brand) for years. Founded in 2006, led by experienced engineers from Taiwan fan companies, we have developed a full range of DC fans for 3D printer. Here, you can find the popular models as below,

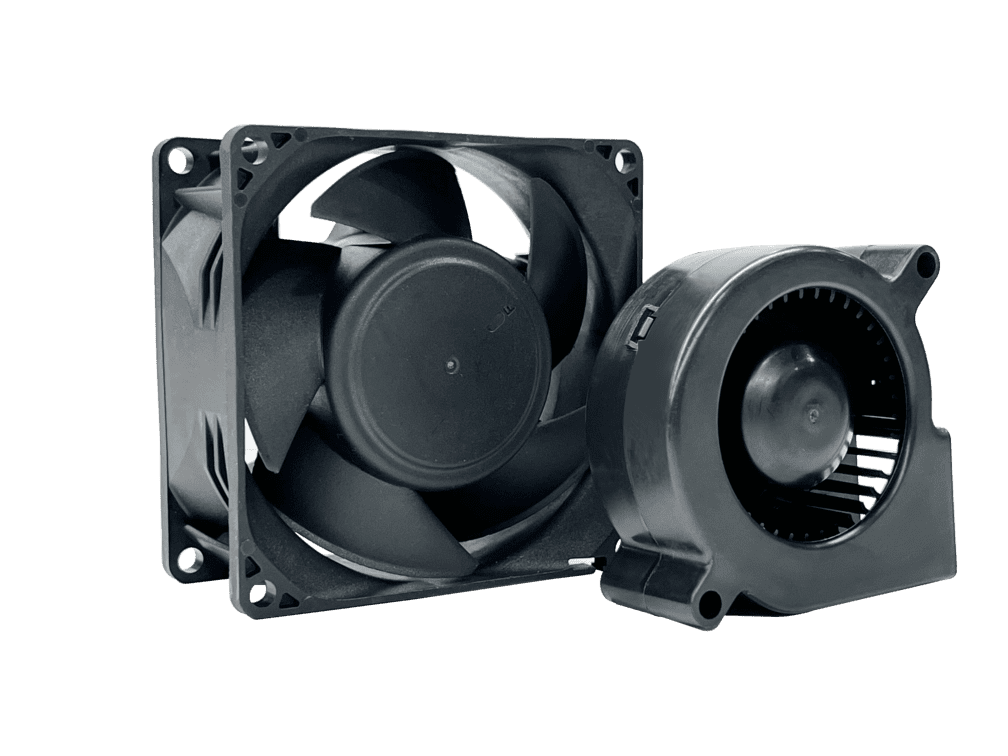

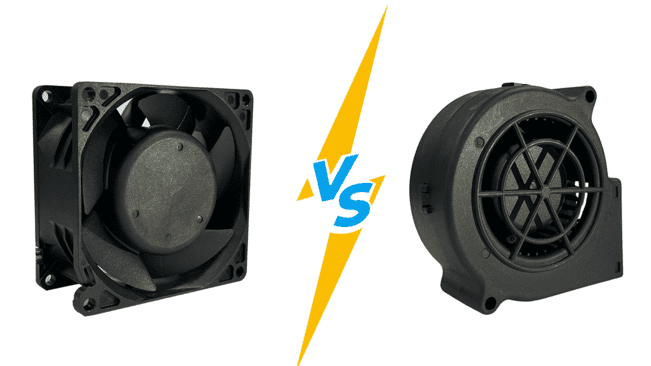

3D Printer DC Axial Fans Series

|  |  |  |  |

| 25x25x10mm Series A | 30x30x10mm Series A (5 Impeller) | 30x30x10mm Series A (7 Impeller) | 35x35x10mm Series B | 40x40x10mm Series A (5 Impeller) |

|  |  |  |  |

| 40x40x10mm Series A (7 Impeller) | 40x40x10mm Series A (11 Impeller) | 40x40x10mm Series G (7 Impeller) | 60x60x15mm Series B (7 Impeller) | 60x60x15mm Series C (9 Impeller) |

3D Printer DC Blower Fans Series

FAQ

- Is a cooling fan necessary for ABS 3D printing?

- The necessity of a cooling fan varies depending on several factors like the shape and size of the object being printed, as well as the characteristics of the ABS material used.

- What’s the optimal fan speed for ABS printing?

- Generally, it’s advised to keep the fan speed between 10% and 30%, especially when printing within an enclosure. Be caution that normally the higher of the ambient temperature in the enclosure, the higher of the cooling fan speed.

- Why is an enclosure recommended for ABS 3D printing?

- An enclosure helps in maintaining a stable internal temperature, which is crucial because ABS is prone to warping due to temperature fluctuations.

- Can I use ABS from different manufacturers interchangeably?

- While it’s possible, be cautious as ABS from different manufacturers can have varying properties. It’s often advisable to test a small print first.

- Is it safe to breathe the air around an ABS 3D printer?

- ABS printing can emit fumes that might be harmful over long-term exposure. Air circulation or filtration systems are recommended when printing with ABS.